描述

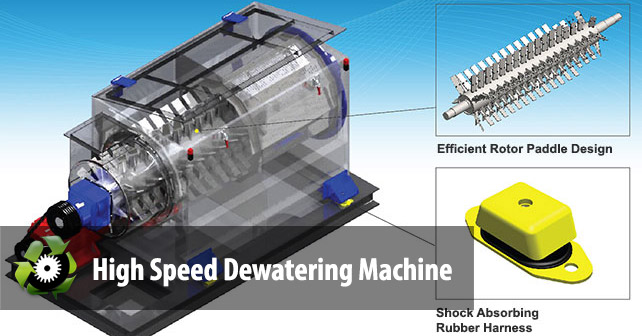

这个是我们标准的PET瓶清洗线的第一道干燥工序,此高速脱水机可以直接脱掉清洗过的PET片的大部分水,为了达到这个效果,离心力被用来把水向外脱。

工作原理

此高速脱水机非常类似于我们的高速洗净机. 两个设备核心部位都是一个装有很多叶片带有电机的轴,轴的周围是一个筛网,整个装置被金属壳体包裹。

脏的PET瓶片被喂入垂直喂料器,旋转的轴以每分钟接近1,000转的速度把PET瓶片往外甩。水通过筛网流出,被收集进行循环利用。而PET瓶片将部分变干,并且进入下一个干燥的工序,通常是热风干燥。总的来说,ASG脱水机将会把PET瓶片的含水量降到大约20%-30%。

型号&说明

| 型号: | 电机功率: | 主轴直径: | 旋转速度: | 产量: |

| HXJ400 | 37KW | 400mm | 1400 RPM | 400 – 800 KG/H |

| HXJ550 | 45KW | 550mm | 1200 RPM | 600 – 1000 KG/H |

| HXJ750 | 55KW | 750mm | 1080 RPM | 1200 – 2000 KG/H |

额外图片

下单

所有单一的设备和标准设备交货期是30天,对于定做的设备或者整线,交货期是60-90天。实际的交货期很大程度上取决于项目的复杂程度以及您下单时我们其它等待做的订单量

联系我们来商谈价格以及订购细节,这个是一个简要的设备订购流程说明.