Description

ASG’s plastic granulator, sometimes referred to as a “crusher”, cuts whole PET plastic bottles into small, uniform pieces, or more popularly known as PET flakes.

Within our PET bottle recycling line, a wet granulator is actually used where an added waterline is implemented to continuously spray water into the cutting chamber. This feature has two important uses:

- The PET flakes are partially cleaned within the wet granulator.

- The water acts as a lubricate lowering friction and heat within the cutting chamber. By adding water to the cutting chamber, we can decrease the frequency of knife sharpening by two to three times.

How It Works

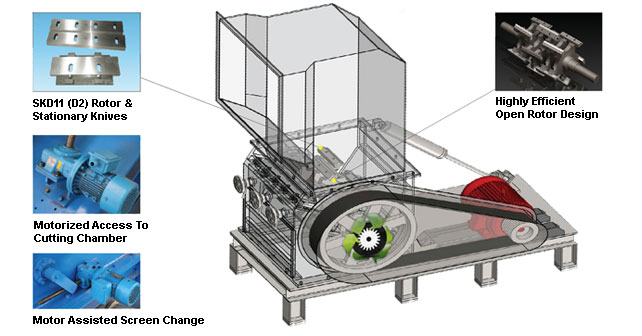

To explain briefly how granulators work, at the core of this robust cutting machine is an open rotor knives mounted with knives in either a double-angle or v-shape array. This rotor, spun by a powerful electric motor, spins at high speeds within a cutting chamber where stationary knives are mounted.

As the PET bottles enter the cutting chamber, the spinning rotor knives come into contact with the stationary knives creating a “scissor cutting” motion. As the rotor continues to spin, the PET bottles are cut into smaller and smaller pieces until they fall through a sizing screen located at the bottom of the cutting chamber.

Models & Specifications

Our standard wet granulator houses 15 rotor and 4 stationary knives. As wear and tear on the knives is extremely high, it is crucial to use only the highest quality knives available on the market today; Hence, all ASG granulator knives are made from SDK11 (equivalent to D2 in the United States) high-carbon, high-chromium steel which ensures longest usage times before requiring sharpening. In addition, all knives are easily adjustable with hydraulic assisted access to the cutting chamber which makes the exchange or sharpening of knives easy and less time consuming.

We offer a variety of granulator models for you to choose from depending on the specifications on capacity in your PET bottle washing line. Below are specifications of our standard granulators.

| Model # | Rotor Diameter | Knife Width | Rotating Speed | Approx. Output | Motor Power |

| SWP630-1000 | ⌀630mm | 1000mm | 470 rpm | 1000 kg/h | 55KW |

| SWP630-1200 | ⌀630mm | 1200mm | 470 rpm | 1200 kg/h | 55KW |

| SWP700-1000 | ⌀700mm | 1000mm | 470 rpm | 1500 kg/h | 75KW |

| SWP700-1200 | ⌀700mm | 1200mm | 470 rpm | 1800 kg/h | 75KW |

| SWP800-1000 | ⌀800mm | 1000mm | 470 rpm | 2000 kg/h | 90KW |

| SWP800-1200 | ⌀800mm | 1200mm | 470 rpm | 2000 kg/h | 90KW |

*Larger, more powerful granulators are available based on your request.

Additional Images

Place an Order

The general lead time for all single-piece, standard equipment orders is 30 days. For custom orders or complete washing lines, the lead time is between 60 – 90 days. The actual lead time will depend heavily on the complexity of the project as well as the amount of machinery we have in queue at the time of your order.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.