PET Recycling Line Description

ASG Recycling Machinery offers state-of-the-art PET bottle recycling lines that can be custom made to your specifications. The main purpose of our PET recycling line is to process PET bottles, such as your typical water bottles, coke bottles, oil bottles, etc, and process them into clean, dry, contaminant-free PET flakes for use in producing polyester staple fiber, PET strapping, PET transparent film & sheets, plastic bottles, or pelletized into granules.

Based on the specifications you give us including your desired capacity, type of PET bottles you plan on processing including they type of contamination you’re expecting, and the quality of RPET flakes, ASG can manufacture a PET bottle recycling line that is custom-tailored to your needs. Our general PET recycling line can handle a capacity between 500KG/H – 3,000KG/H, however, higher capacities can be achieved.

For more detailed, feel free to contact us or visit our factory to speak face-to-face.

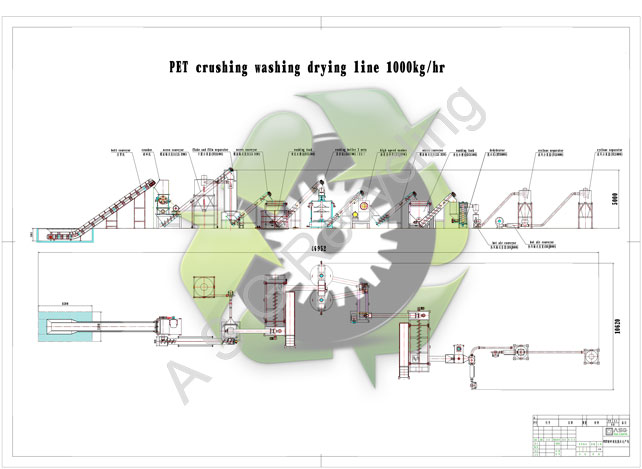

PET Recycling Line Diagram

Below is our standard 1,000 KG/H PET bottle recycling line diagram.

[click to enlarge PET Recycling Line Diagram]

PET Bottle Recycling Line Machinery

Below is a list of recycling equipment used in our PET bottle recycling lines in order. While machinery used are the same across various models of PET recycling lines, the capacity of each piece of equipment as well as the use of multiple equipment will differ based on your specifications for capacity and quality of PET flakes.

- Bale Opener

- Rotary Trommel

- Shorting Belt w/ Metal Detector

- Wet Grinder

- Label Remover

- Sink-Float Separation Tank (2x)

- Hot Steam Washer

- Friction washer

- De-watering / Centrifugal Dryer

- Hot Air (Thermal) Spiral Pipe Dryer

- Product Silo

- Electric Control Cabinet w/ PID Central Computer

- Water Filtration / Recycling System

*Screw and belt conveyors are used to connect each piece of machinery.

Typical PET Flakes Quality

Our standard PET bottle recycling produces PET flakes that are highly decontaminated via the most environmentally friendly practices using the lowest possible amounts of water and manpower.

- Moisture: < 1%

- Bulk density: < 0.3G/CM3

- Total impurity: < 100ppm

- PVC content: < 40ppm

- Metal content: < 10ppm

- PE/PP content: < 50ppm

- Particle size: < 14-16mm

Images

Place An Order

The general lead time for all single-piece, standard equipment orders is 30 days. For custom orders or complete washing lines, the lead time is between 60 – 90 days. The actual lead time will depend heavily on the complexity of the project as well as the amount of machinery we have in queue at the time of your order.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.